Services

[Fabrication]

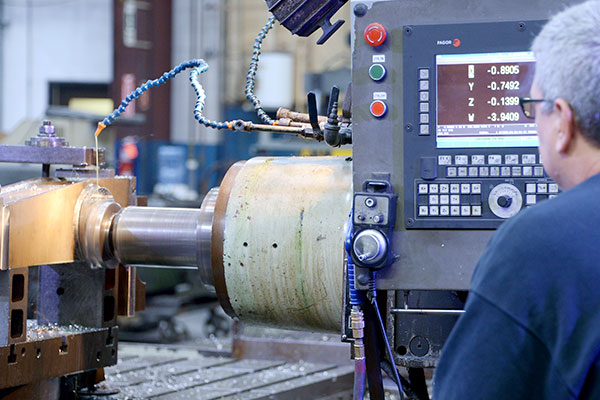

Miller Industrial Manufacturing has manufacturing facilities covering over 55,000 square feet with 35,000 sq. ft. dedicated to fabrication alone.

We are a customer-driven metal fabrication shop specializing in ASME pressure vessels, storage tanks, heat exchangers, and system components for industrial processes. A broad range of products and services is provided to a diverse group of clients in the pulp and paper industry as well as many others.

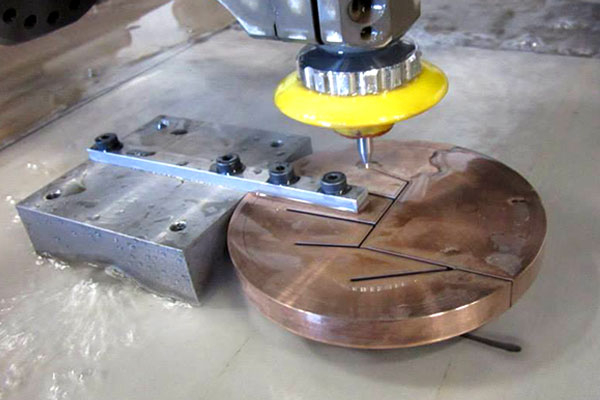

Our fabrication facilities include the ability to waterjet, burn/cut, roll and form carbon, stainless and Duplex steels as well as other materials, including titanium. We engage our skilled welders who are tested and qualified in FCAW, GMAW, GTAW, SMAW & SAW to join these materials.

From engineering to assembly and delivery, we do it all.

Fabrication Equipment

Miller Industrial Manufacturing’s fabrication shop is completely equipped and allows our experienced fabricators to work on a multitude of projects.

- (3) Mach4 Flow Dynamic Waterjet XD

- Computerized cutting table, Lone Star Ranger III 12′ x 24′ with Hypertherm XPR300 plasma system

- H-D Pipe Rotary for up to 24″ pipe and 60-degree articulating bevel head

- Betenbender Shear – 12′ x 5/8″

- (4) Bug-o Circle cutting systems

- (3) Gullco Kat Track cutting tractors

- Hyd-Mech S20 series 3 – 18″ horizontal saw with computerized feed table

- Spartan Marvel 180-ton hydraulic dual station ironworker

- Hyd-Mech Vertical 18″ band saw

- (11) Plasma Arc cutting machines (1/8″ to 4″ capacity)

- Vernon Model G Pantograph 60″ diameter pipe cutting system

- Bertsch 100-10 Hydraulic forming roll – 10′

- Cincinnati 350 Ton CBII x 12′ hydraulic press brake

- Dreis Krump 1250 Ton x 16′ fully computerized hydraulic press brake

- Ercolina TB100 Top Bender Rotary Draw Tube and Pipe Bender

- Misc. H Press and Straighten Presses

- Roundo R5S Angle/Pipe/Bar/Channel Forming Roll

- (2) small hand/Electric Forming Rolls

- Webb R3LD-8005 3 Roll 5′ Plate Forming Roll

- Webb 912A 3 Roll 9′ Plate Forming Roll

- (3) Aronson 4000 lbs. Positioners

- (4) Leveling Beads

- (7) Forklifts (2,000 – 11,000 lbs.)

- Ransom 30,000 lbs. Positioner

- Multiple sets Tank Turning Rolls (500 – 150,000 lbs.)

- (3) Teledyne 1000 lbs. Positioners

- 5 Ton Overhead Crane

- 10 Ton Overhead Crane

- 15 Ton Gantry Crane with Hooks

- (1) 25ton capacity dual hook

- (1) 50 ton capacity dual hook, with 29′ under the hooks

- (2) Tractors w/Various Flatbeds, Drop Decks and Boxed Trailer

- (4) 1 Ton Trucks with Trailers for Hot Shot Deliveries

- Worthington 6000 lbs. Positioner

- (8) Bug-o Weld Overlay Machines

- Gullco GBM28 Weld Prep Machine

- (3) 650 Amp Hand Held Sub Arc Systems

- (9) Miller XMT 450 MPa (multi-process mig machines)

- (60) Lincoln DC655 Welding Machines

- (4) Miller Delta Weld 452 Mig Machines with Feeders

- Pandjiris Model 1400-MANIP 14′ Vertical x 14′ Horizontal, 1000 Amp Sub Arc System w/Flux Heating and Recovery. 120,000 lbs. turning capacity

- (30) Weldcraft Tig Units (air and water cooled)

- Time-saver series 3100 – 36″ wide abrasive finishing belt with water cooling

- Ceramic media tumbler