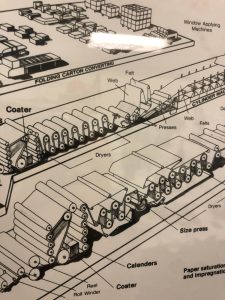

Pictured are paper machine dryer sections that dry and remove the water by way of a series of internally steam-heated cylinders that evaporate the moisture from the paper web. Below are the dryer cans refurbished by Miller by grinding the outside via the lather, cleaning the journals, replacing the bearings, and reworking the header. The cans are then U.T’d and hydro tested for leaks. Finally, they are blasted and painted to look like new. The final picture is where the dryer cans are located within the paper-making process.